Industrial Cabling

Developed by the TIA TR-42.9 Industrial Infrastructure Subcommittee in May 2012, and reaffirmed in March, 2020, the ANSI/TIA-1005-A Standard "Telecommunications Infrastructure Standard for Industrial Premises" helps in the planning and installation of telecommunications cabling within and between industrial buildings, providing framework around infrastructure, distance, telecommunications outlet/connector configuration, and topology. The potential exposure to hostile environments in the industrial space is the central concept of the Standard in contrast to that of ANSI/TIA 568, which addresses commercial buildings, with the special cabling system requirements of industrial operations also a prime design principle of the document.

ANSI/TIA-1005-A content

- Industrial Areas

- Telecommunications Spaces

- Telecommunications Pathways

- Firestopping

- Backbone Cabling (Cabling Substem 2 and 3)

- Horizontal Cabling (Cabling Subsystem 1)

- Work Area

- Grounding and Bonding

- Industrial Cabling Performance Requirements

- Annexes addressing Requirements and Guidelines for Two-Pair, 100 Ohm Balanced Twisted-Pair Cabling, Guidance on Using More Than Four Connections in a Channel, and Extending Fiber Optic Channels

The main differences between the TIA-1005 and TIA-568 Standard are:

- Allows for 2-pair cabling (M12) systems

- Defines an "automation island"

- States that Category 6 or better cabling shall be used for the automation islands

- Defines "automation" outlets and cables

- Defines environmental concerns in concrete terms

- Includes (M.I.C.E.) M123 I 123 C123 E123 definitions

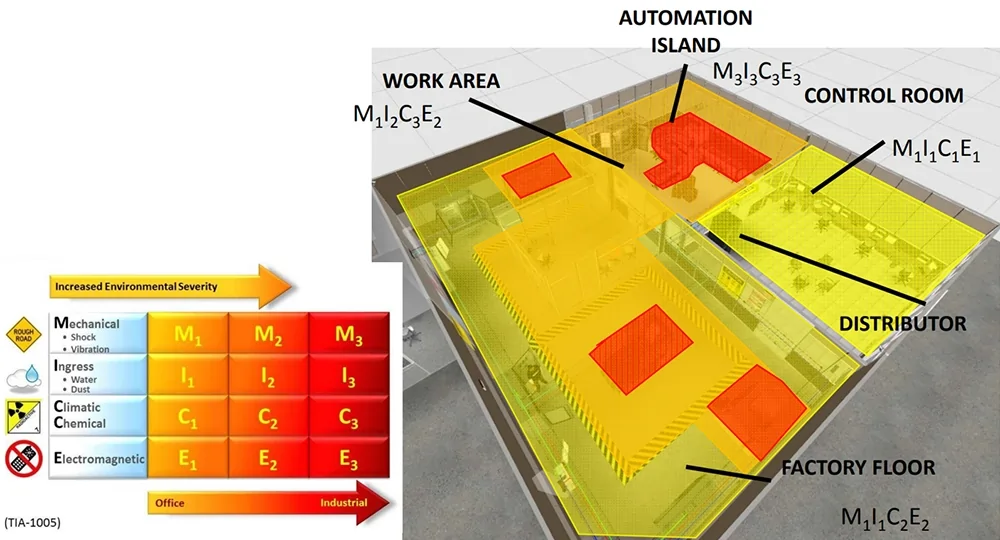

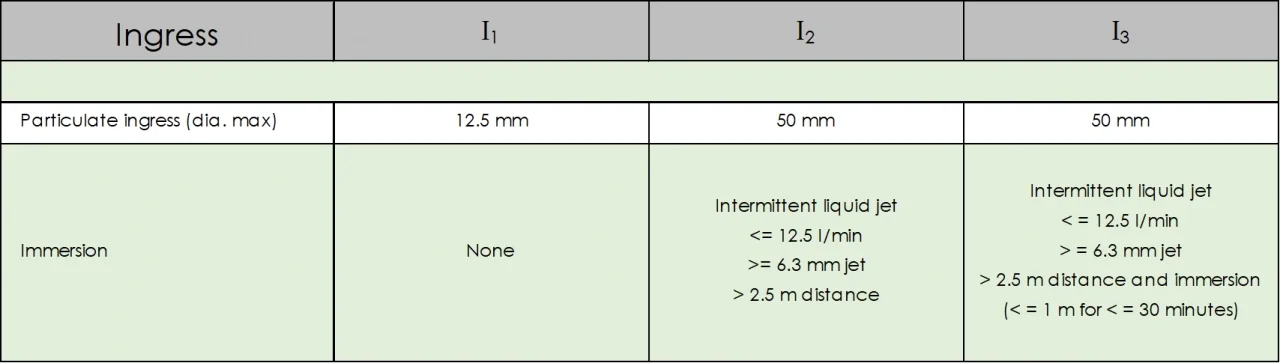

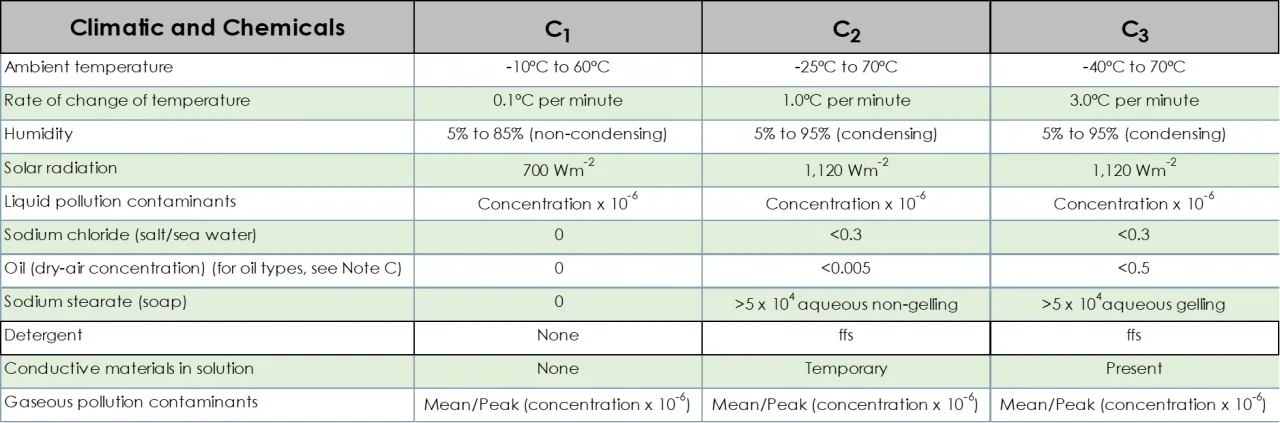

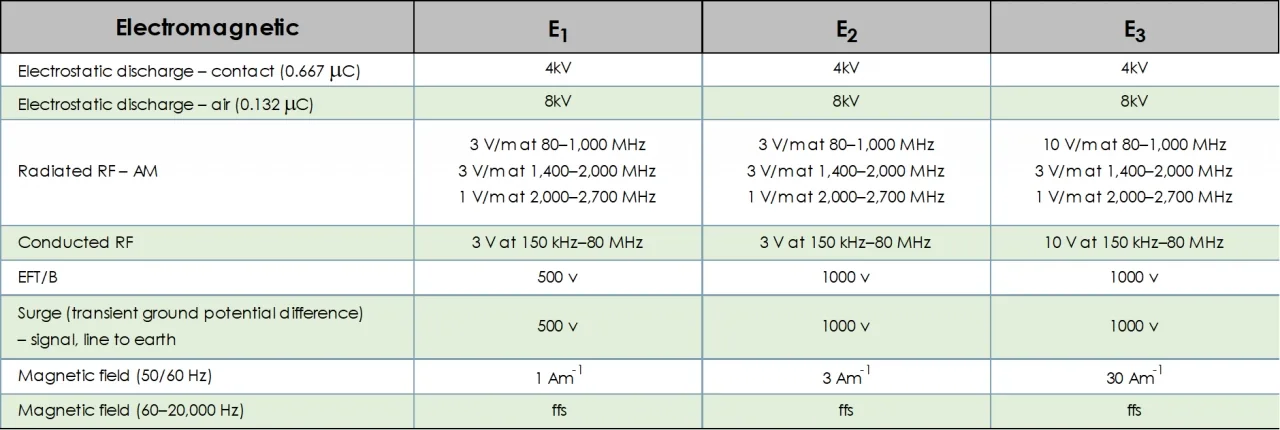

The M.I.C.E (Mechanical, Ingress, Climate/Chemical, Electromechanical) concept is based upon the assumption that cabling, even under the worst conditions, is still protected and guarantees reliable network operation. Its purpose is to help understand the environment class as best you can, enabling you to design a reliable network even in the toughest environments.

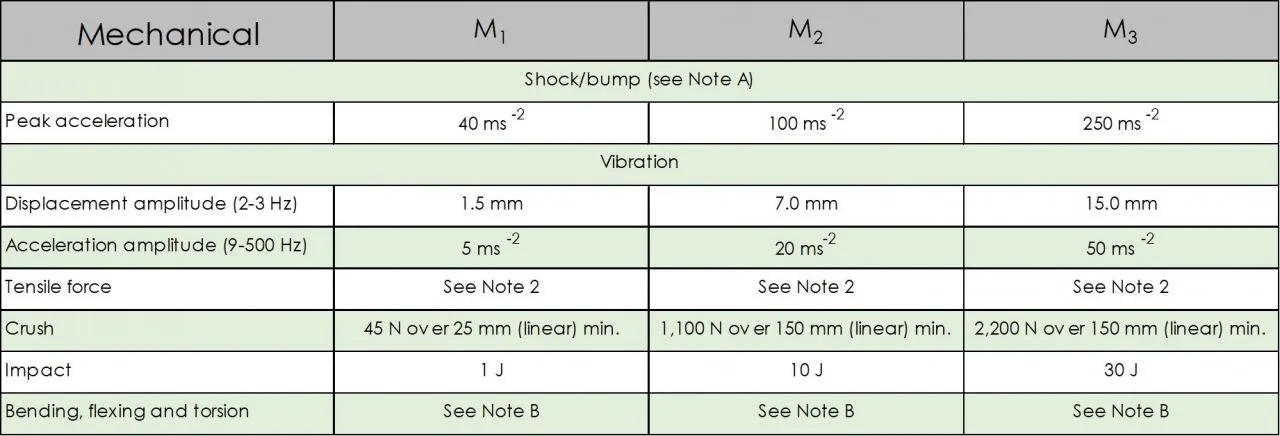

There are three severity classifications, numbered 1, 2 or 3:

- M1I1C1E1 describes the classification for a typical commercial building according to ISO/IEC 11801 or ANSI/TIA 568D

- M2I2C2E2 describes a worst-case light industrial environment

- M3I3C3E3 describes the harshest industrial environment

The three basic types of industrial areas include:

- Factory Floor (MICE 1 or 2)

- Work Area (MICE 2 or 3)

- Automation Island (MICE 3)

- The areas have mixed environments and are given classifications (subscripts 1, 2 and 3) based on the MICE limits assigned to that level of hazard.

Note A: The repetitive nature of the shock experienced by the channel should be taken into account.

Note B: This aspect of environmental classification is installation-specific and should be considered in association with the appropriate specification.

Note C: This aspect of environmental classification is installation-specific and should be considered in association with the appropriate specification.

Sample industries and environments

What is an IP rating?

An IP rating, also known as Ingress Protection or International Protection ratings, are defined to the international standard of EN 60529. This standard is used to define the levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies such as tools, dirt and moisture.

The rating consists of the letters IP followed by two digits, the higher the number the better the protection. Sometimes a number is replaced by X, which indicates that the enclosure is not rated for that specification.

The first digit indicates the level of protection that the enclosure provides against the ingress of solid foreign objects, from tools or fingers that could be hazardous if they came into contact with electrical conductors or moving parts, to airborne dirt and dust that could damage circuitry. The second digit defines the protection of the equipment inside the enclosure against various forms of moisture (drips, sprays, submersion etc).

IP65 Enclosure - IP rated as "dust tight" and protected against water projected from a nozzle

IP66 Enclosure - IP rated as "dust tight" and protected against heavy seas or powerful jets of water

IP67 Enclosures - IP rated as "dust tight" and protected against immersion (to 1mtr)

IP68 Enclosures - IP rated as "dust tight" and protected against complete, continuous submersion in water

Industrial cabling - what cabling to use and where

Cabinet or control rooms / low vibration

Where vibration is limited. In these applications, a solid conductor is the right choice. Future-proofed with high bandwidth capability.

Factory floors / moderate vibration

For the factory floor and work areas where there are raised levels of vibration. Cables are also likely to be exposed to oil, chemicals, rough handling, abrasion, UV radiation, temperature variations and electronic noise (EMI and RFI).

On machine / high vibration

For use on machines where vibration and temperatures are high to very high. In this case the need is for flexible cabling. Resistant to trailing and torsion, with a good level of connectivity protection against liquids. Minimum IP67 protection connectivity.

Exterior Cabling

Where vibration and temperatures can be above normal. UV exposure likely. Exposure to weather/moisture. Mechanical protection for exposed cable. Possibly installed aerially.

Data rate requirements

Jacket options

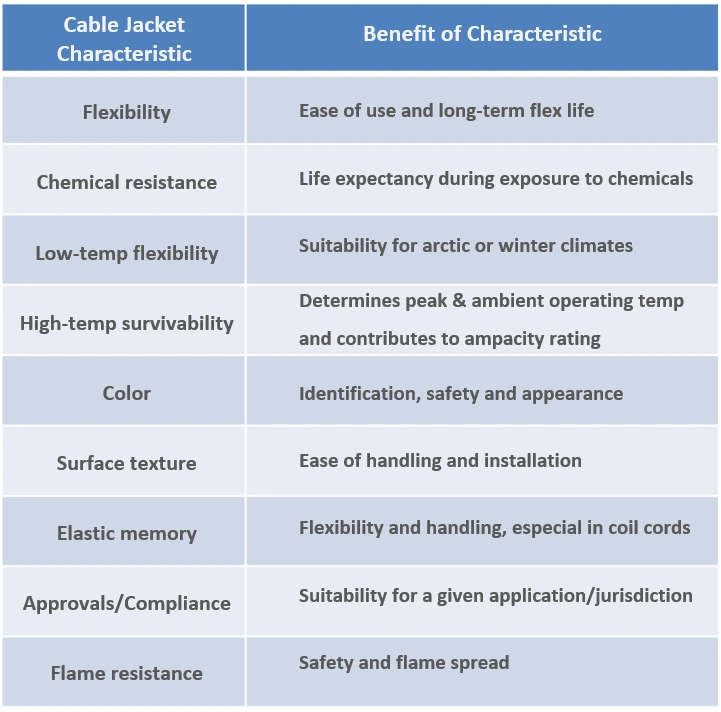

What cable jacket characteristics do you need?

In most exterior and industrial applications, a physically robust cable jacket is needed because the environment may be harsh – either above or below ground.

Some common cable jacket characteristics to consider when choosing an the cable that's right for you are listed in the table to the left.

There are many types of cable jackets available. It's important to consider the jacket type when selecting the compatibility with the application's connectors and environment.The table below contains typical characteristics of some of the most common jacket types used both indoors and outdoors for most cables:

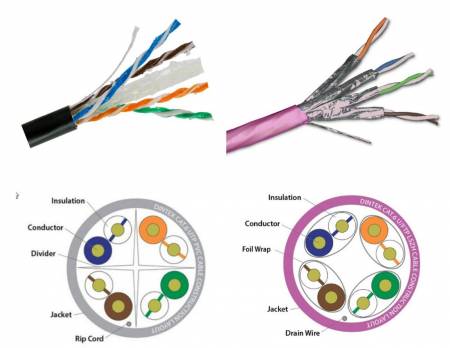

Shielded vs unshielded

Unshielded cable pros

- More lightweight, thin and flexible than their shielded counterparts. This means unshielded cables can be used more easily in non-industrial settings.

- They are cheaper to manufacture, and as a result, also cheaper to buy. A lot depends on the quality as well. A high-quality unshielded cable can last you for many years, while a similar cable of poor quality can break within months.

- They are easier to install and maintain than shielded cables. If you compare the ease of installation, even untrained professionals find it easy to set up unshielded cables.

- Reduces electrical noise created by electromagnetic signals without affecting the signal strength.

- Helps reduce the level of electromagnetic radiation that might occur. This radiation, if allowed to affect nearby machines for extended periods of time, can cause the system to break down.

- Minimizes the capacitively coupled noises emanating from other sources of electricity. This noise can be a constant source of annoyance for nearby workers, and may even decrease productivity.

- Shielded cables, in general, are built to last longer and take more punishment than unshielded cables. That is why they are the preferred choice for industrial and factory use.

Metal protection

Many people may think that armored cable just has metal protection, however the armoring material doesn't have to be metal. It can be fiber yarn, glass yarn, polyethylene etc.

There are a few reasons why armored cable could be used, the biggest reason is about strength. Rodents or animals can and will chew through cables so the armor protects the cables from damage. Lastly, the armor when grounded can provide another layer of RF protection. Armored cables MUST always be grounded!

DINTEK'S IP67 CABLING PRODUCTS ACHIEVE CAT.5E AND CAT.6A PERFORMANCE AND CLASS IP67 PROTECTION

Connection hardware

DINTEK's IP67-rated connection hardware range guarantees excellent protection against liquid and solid agent penetration.

Plugs & Adaptors

Plugs are used for terminating industrial cabling direct to industrial cabling or industrial patch cord cable. Adaptors are used for joining DuraMAX-67TM patch cords used for patching between automation devices and controls in harsh environments or adverse conditions. Commonly used in the manufacturing, automotive, petro-chemical, mining and building automation markets. IP67 protection allows patch plugs and cords to withstand harsh factory environments (e.g wash down and temporary submerged conditions) without any loss of performance to the link. 100% performance tested.

Keystone Jacks

Protects against the effects of industrial vibrations, and allows for extended life & reliable performance. Endures high UV, humidity, oily and acidic environments.

Meets IP67 standard

Meets UL 1863 compliant

Operating Temperature : -25ºC to 70ºC

A durable and fully enclosed design

Mounting Boxes

Stainless steel surface providing anti-corrosive & waterproof protection. Contains face plate & back mounting box kit. Endures high UV, humidity, oily and acidic environments.

Meets IP67 standard

UL 1863 compliant

UL safety verified

Operating Temperature : -25ºC to 70ºC

A durable and fully enclosed design.

Patch Cords

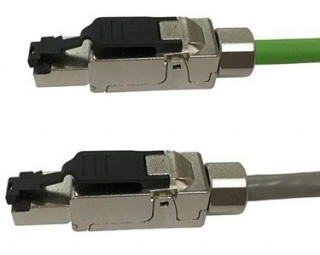

Field Terminated Plugs

The plugs feature a fully shielded die-cast housing; are highly durable and designed for easy installation and field termination. They are available in Cat.5e, Cat.6 and Cat.6A compliant component versions. Effortless termination has been achieved without the need to use a tool.

Faceplates

Protects against the effects of industrial vibrations, and allows for a extended life & reliable performance. Endures high UV, humidity, oily and acidic environments.

Meets IP67 standard | Meets UL 1863 compliant

Operating Temperature : -25ºC to 70ºC. A durable and fully enclosed design