Top 10 Installation Errors That Reduce Network Performance — and How to Avoid Them

High-performance networks often don’t fail because of the cable or the category rating — they fail because of the way those cables are installed. Most performance problems can be traced to simple mistakes that happen in ceilings, risers, and comms rooms every day.

Here are the 10 most common installation errors, what they do to the network, and how to avoid them.

Ignoring Bend Radius

Over‑bending copper or fiber cables can cause micro‑damage, leading to higher loss and intermittent errors that are hard to diagnose. This is especially critical in high‑density racks and tight pathways where installers are tempted to “make it fit” instead of maintaining the minimum bend radius.

Practical fixes include planning pathways carefully, using proper support hardware, and training installers to recognise bend‑sensitive areas like the rear of patch panels and equipment. Simple visual inspections during commissioning often catch problem areas before they become service issues.

Exceeding Untwist Limits at Terminations

Untwisting too much conductor at jacks or patch panels destroys the pair balance that keeps crosstalk under control. Even small deviations from the recommended untwist limit can show up as poor performance on higher‑bandwidth links.

Consistent termination practices, clear work instructions, and quality jacks that guide pairs into place all help reduce the risk. A quick certification test at the end of each link confirms that untwist has been kept within acceptable limits.

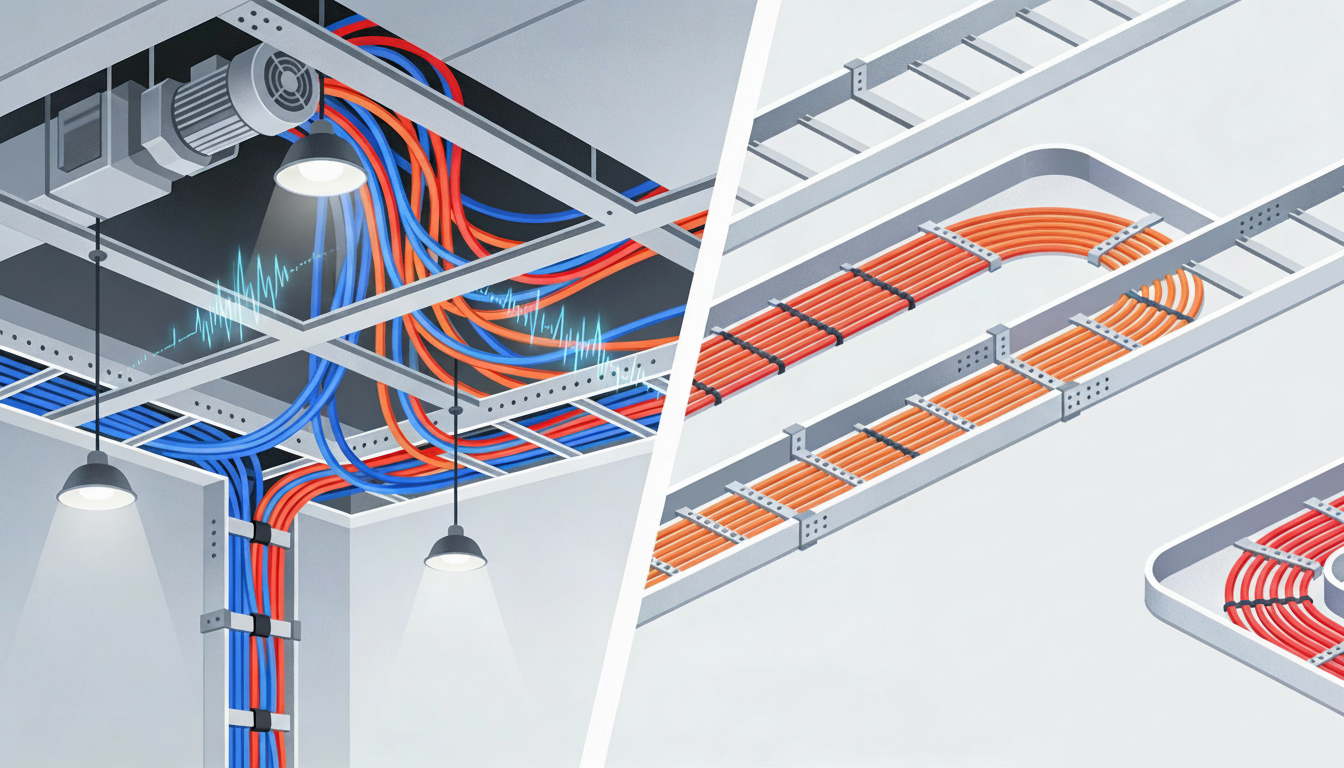

Poor Cable Routing and Segregation

Running data cables alongside power circuits, lighting, or motors introduces electromagnetic interference that erodes signal quality. Bundling too many copper cables tightly together, especially in 10G installations, can increase alien crosstalk.

Best practice is to separate power and data where possible, respect fill ratios, and avoid tight bundles over long distances. When planning a new installation, build segregation and pathway capacity into the design rather than trying to retrofit it later.

Exceeding Maximum Channel Length

Cable runs that push beyond the 100‑metre limit for copper Ethernet, or ignore patch cord lengths, can appear fine at first but fail once real traffic or PoE loads are applied. Excessive length increases attenuation and delay, undermining higher‑speed applications.

A simple discipline of measuring and documenting runs during installation goes a long way. Using certification testers that report length and margin, rather than just continuity, helps ensure every channel stays within design limits.

Using Low-Quality or Mismatched

COMPONENTS

Where possible, specify an end‑to‑end cabling system from a reputable vendor so components are designed and verified to work together. For example, DINTEK’s structured cabling ranges – including matched patch cords, patch panels, and jacks – are engineered as complete channels rather than standalone parts, helping maintain performance and certification margins.

Skipping Full Standards-Based Testing

Relying on basic continuity checks or a “link up” light misses deeper issues like return loss, crosstalk, and resistance imbalance. Without documented, standards‑based testing, troubleshooting and warranty discussions become slower and more contentious.

Implementing a test‑and‑document policy for every permanent link – copper and fiber – gives everyone a clear baseline. DINTEK’s certification testers fit naturally here, providing a full suite of standards‑aligned measurements and structured reports without adding excessive time on site.

Inadequate Planning and Documentation

Rushing into installation without a clear design, labelling scheme, or record‑keeping process leads to rework, wasted materials, and difficult future MACs. Poor documentation also makes it harder to link test results to physical locations.

Simple measures such as consistent outlet numbering, rack layouts, and as‑built drawings pay off quickly. When combined with digital test records, they give IT teams and facility managers an accurate map of the cabling they rely on.

Neglecting Environmental Conditions

Heat, moisture, dust, and mechanical stress all affect cabling performance over time. Using the wrong jacket type or connector style in plenum spaces, industrial areas, or high‑humidity environments can shorten service life.

A basic environmental survey during design helps identify areas that need higher‑specification cabling or enclosures. DINTEK’s range includes options for more demanding conditions, so installers can match product selections to real‑world environments instead of assuming “one size fits all”.

Poor Patching and Cable Management

Unlabelled cords, tangled patch fields, and unsupported cables hanging from panels put mechanical stress on terminations and increase human error. Over time, these stresses can cause intermittent disconnections that are difficult to trace.

Disciplined patching, labelling, and the use of cable managers, Velcro ties, and strain relief hardware all extend the life of the installation. DINTEK patch panels and management accessories are designed to support tidy, serviceable front‑of‑rack layouts without slowing technicians down.

Failing to Re-Test After Changes

Moves, adds, and changes introduce new risk every time a link is re‑terminated, re‑routed, or repatched. Without re‑testing, latent faults can remain hidden until they impact critical applications.

Adopting a “test every change” mindset, backed up by quick autotests rather than full recertification when appropriate, helps catch these issues early. Portable handheld testers from brands such as DINTEK make it realistic to verify work on the spot before leaving site.

Turning Common Errors into Good Practice

Avoiding these ten installation mistakes is as much about process and culture as it is about technology. By combining standards‑aligned practices, sensible planning, and selective use of DINTEK’s cabling, testers, and management tools, installers can deliver networks that perform to spec on day one and keep doing so for years.