Advancements in smaller diameter Cat.6A cables: Optimising performance and installation efficiency

As the use of 10GBASE-T ports continues to expand, Category 6A channels are becoming the standard for new cabling installations in order to support the higher 10-gigabit data rates. As legacy networks are upgraded to 10GBASE-T equipment, lower-category cable infrastructure such as Cat.6 and Cat.5e will also need to be upgraded to Cat.6A.

However, typical Cat.6A cabling is larger in diameter compared to the legacy cables. This is due to the alien crosstalk requirements imposed on Category 6A channels, which results from unwanted electromagnetic coupling between conductors in adjacent cables that are tightly bundled together.

Creating more physical separation between the conductors of adjacent cables is a simple and direct method to reduce the coupling between them, which is achieved by increasing the cable diameter. This has been proven effective in early Cat.6A cable designs, but it comes at a price of larger cable diameters. Larger diameter cables reduce the effective capacity of cable routing infrastructure such as raceways and ladder racks. Moreover, larger diameter Cat.6A cabling may require more cable management elements compared to Cat.6 and 5e, which can make it too expensive or impossible for some networks to upgrade to Cat.6A cabling.

To manage this, cable designers have focused on reducing the diameter of Cat.6A cables while still meeting the alien crosstalk requirements. Over the years, they have put great effort into developing Cat.6A cables that have smaller diameters but still provide the necessary protection against alien crosstalk, allowing for easier installation and management of Cat.6A cabling while still supporting the higher data rates required by modern networks.

How has this been achieved? Read on!

However, typical Cat.6A cabling is larger in diameter compared to the legacy cables. This is due to the alien crosstalk requirements imposed on Category 6A channels, which results from unwanted electromagnetic coupling between conductors in adjacent cables that are tightly bundled together.

Creating more physical separation between the conductors of adjacent cables is a simple and direct method to reduce the coupling between them, which is achieved by increasing the cable diameter. This has been proven effective in early Cat.6A cable designs, but it comes at a price of larger cable diameters. Larger diameter cables reduce the effective capacity of cable routing infrastructure such as raceways and ladder racks. Moreover, larger diameter Cat.6A cabling may require more cable management elements compared to Cat.6 and 5e, which can make it too expensive or impossible for some networks to upgrade to Cat.6A cabling.

To manage this, cable designers have focused on reducing the diameter of Cat.6A cables while still meeting the alien crosstalk requirements. Over the years, they have put great effort into developing Cat.6A cables that have smaller diameters but still provide the necessary protection against alien crosstalk, allowing for easier installation and management of Cat.6A cabling while still supporting the higher data rates required by modern networks.

How has this been achieved? Read on!

Alien crosstalk and mylar-coated foil tape

To address the issue of alien crosstalk, manufacturers researched how to shield the cable for 10G. A technique was introduced that utilizes a metallic foil barrier with segments wrapped around twisted pairs. This technique works by attenuating the magnetic coupling from adjacent cables, which induces a current in victim pairs proportional to the aggressor's magnetic field. The metallic foil creates an opposing magnetic field to the aggressor's field, resulting in a reduction of the aggressor's magnetic field seen by the victim pairs.

As a result, smaller-diameter cables can be bundled together while still meeting alien crosstalk requirements. This cable can be used with UTP 6A connectors and does not require grounding, but it must be terminated like any UTP cable. Different manufacturers have different methods of achieving this, but they sell 6A cable that is "shielded" without needing grounding.

Advantages of a smaller diameter for Cat.6A UTP cable

Improved flexibility and maneuverability: Smaller diameter cables are more flexible and easier to bend, making them convenient for installation in tight spaces, conduits, or cable trays. They allow for easier routing and maneuverability, simplifying the installation process and reducing the effort required.

Space optimization: Smaller cables take up less physical space, which is particularly beneficial in crowded data centers or networking environments. They enable better cable management, reduce congestion, and make it easier to maintain a neat and organized setup.

Enhanced airflow and cooling: By occupying less space, smaller diameter cables contribute to improved airflow within cabinets and racks. This helps maintain optimal temperature conditions and prevents overheating of network equipment. Efficient cooling is essential for equipment reliability and longevity.

Space optimization: Smaller cables take up less physical space, which is particularly beneficial in crowded data centers or networking environments. They enable better cable management, reduce congestion, and make it easier to maintain a neat and organized setup.

Enhanced airflow and cooling: By occupying less space, smaller diameter cables contribute to improved airflow within cabinets and racks. This helps maintain optimal temperature conditions and prevents overheating of network equipment. Efficient cooling is essential for equipment reliability and longevity.

Higher cable density: The reduced size of Cat.6A UTP cables allows for higher cable density in networking infrastructure. With smaller diameters, more cables can be accommodated within the same space, enabling increased connectivity without the need for additional physical resources.

Easier cable management: Smaller diameter cables are more manageable during installation and ongoing maintenance. Easier to bundle, label, and organize, it simplifies cable management tasks, leading to a tidier and more efficient networking environment, reducing the risk of cable damage and facilitating troubleshooting if issues arise.

Cost savings: Smaller diameter cables generally require less material during manufacturing, resulting in potential cost savings. Additionally, they may require smaller conduits, cable trays, or containment systems, reducing installation and infrastructure costs.

Easier cable management: Smaller diameter cables are more manageable during installation and ongoing maintenance. Easier to bundle, label, and organize, it simplifies cable management tasks, leading to a tidier and more efficient networking environment, reducing the risk of cable damage and facilitating troubleshooting if issues arise.

Cost savings: Smaller diameter cables generally require less material during manufacturing, resulting in potential cost savings. Additionally, they may require smaller conduits, cable trays, or containment systems, reducing installation and infrastructure costs.

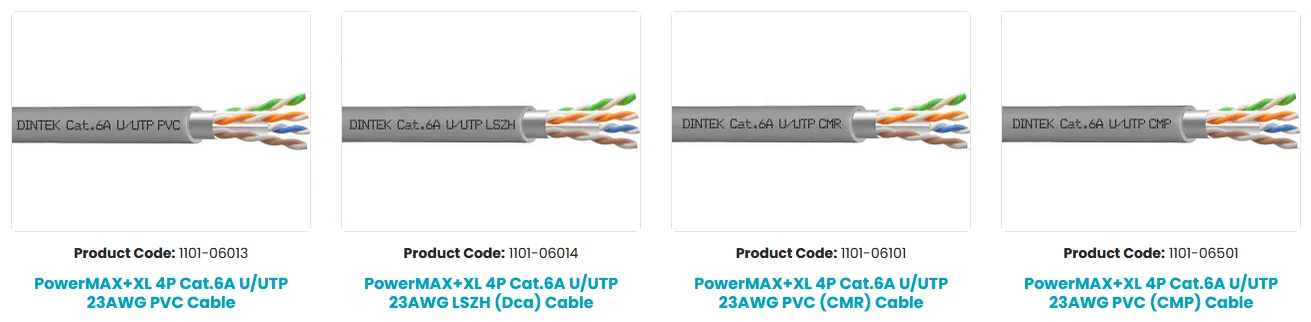

DINTEK'S new PowerMAX+XLTM slimline foil wrapped UTP cable contains a foil tape with dual-sided mylar coating which surrounds all four pairs. This cable can be made smaller than non-tape U/UTP Cat.6A cables, while maintaining excellent performance and maximum ANEXT suppression.

Click here to see the full DINTEK PowerMAX+XLTM range of products