When safety is on the line—in data centers, hospitals, high-rise buildings, transport hubs, and confined spaces—Low-Smoke, Zero-Halogen (LSZH) cabling isn't just an option. It’s a requirement. But here’s the issue: not all LSZH cables are created equal. And worse, not every “LSZH” label you see in the market is backed by actual compliance testing.

So what does it really mean for a cable to qualify as LSZH, and how can installers, contractors, and end-users be confident they’re protected?

What is LSZH?

LSZH stands for Low-Smoke, Zero-Halogen. These cable jackets are engineered to:

Emit minimal smoke when exposed to fire

Release no toxic halogen gases such as chlorine or fluorine

Prevent corrosive damage to nearby equipment

Improve visibility and survivability during evacuation or firefighting operations

Because they mitigate toxic gases and equipment damage, LSZH cables are frequently mandated in environments where lives and mission-critical technology are at risk. But with limited regulatory oversight in parts of the world, the LSZH label has sometimes become more of a marketing term than a verified safety rating.

Claims vs. Certified Performance

Here lies the danger: many manufacturers promote “LSZH cables” without proof of compliance. No independent testing. No traceable certification. No assurance for the installer or end-user.

The consequences of relying on non-compliant cables are serious:

Toxic smoke inhalation in the event of a fire can be lethal.

Corrosive gas emissions can destroy servers, switches, and other sensitive IT infrastructure.

Legal liability may fall on contractors or system integrators who installed products that fail to meet standards.

What Makes a Certified LSZH Cable Different?

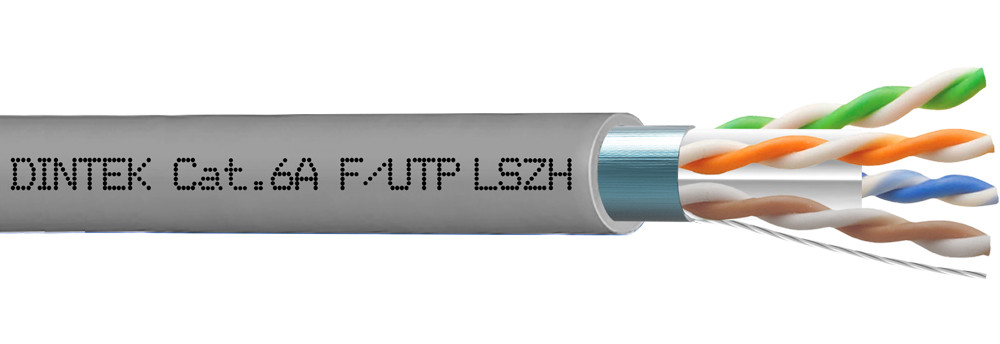

DINTEK Electronic takes compliance further than marketing claims. We back every LSZH product with independent third-party testing, clear documentation, and strict manufacturing controls.

DINTEK LSZH: Proof, Not Promises

Complete Documentation

Every certified reel is traceable. We can provide test reports, lot numbers, and production data—so you always know exactly what you’re installing.

Third-Party Verified Compliance

DINTEK LSZH cables are tested against internationally recognized standards, including:

IEC 60332-1 / IEC 60332-3 (flame propagation tests)

IEC 61034-2 (smoke density tests)

IEC 60754-1/2 (acid gas and halogen content tests)

Strict Manufacturing Quality Control

Using premium-grade polymer compounds, DINTEK production facilities operate under ISO-certified procedures to ensure durability, consistency, and safety.

On-Site Burn Testing

DINTEK operates its own on-site burn test laboratory. All products are tested to the latest international safety standards, ensuring quality and compliance at every stage.

Proven Global Use

Using premium-grade polymer compounds, DINTEK production facilities operate

under ISO-certified procedures to ensure durability, consistency, and safety.

The Bottom Line: Don't Take Chances

DINTEK International takes compliance further than marketing claims. We back every LSZH product with independent third-party testing, clear documentation, and strict manufacturing controls.

When lives, critical networks, and equipment longevity are on the line, compliance is non-negotiable. Choosing a cable that claims LSZH—without certification—could expose you to safety risks, liability, and catastrophic losses.

With DINTEK LSZH cables, you get proof, not promises.

Choose DINTEK. Choose safety.

For more information, contact your local distributor or email: