Product Code:

1505-05001

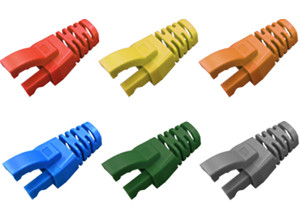

DuraMAX Cat.6A RJ45 Industrial STP Plug

Force Technology Certification

Who We Are

Established in 1990 our fundamental goal is to build positive, long-term relationships with our customers. Relationships characterized by quick response to customer needs and concerns, and by a strong commitment to developing new products and services of the highest quality, value and usefulness. The growth of our customers brings us the greatest satisfaction.

Upcoming Events

There are currently no up-coming DINTEK events